CORIOLIS: The process

Process

A full scale drawing is created.

The lower half profile is cut out of 3/4” plate glass in 2 pieces and sandblasted.

The 2 halves are glued together.

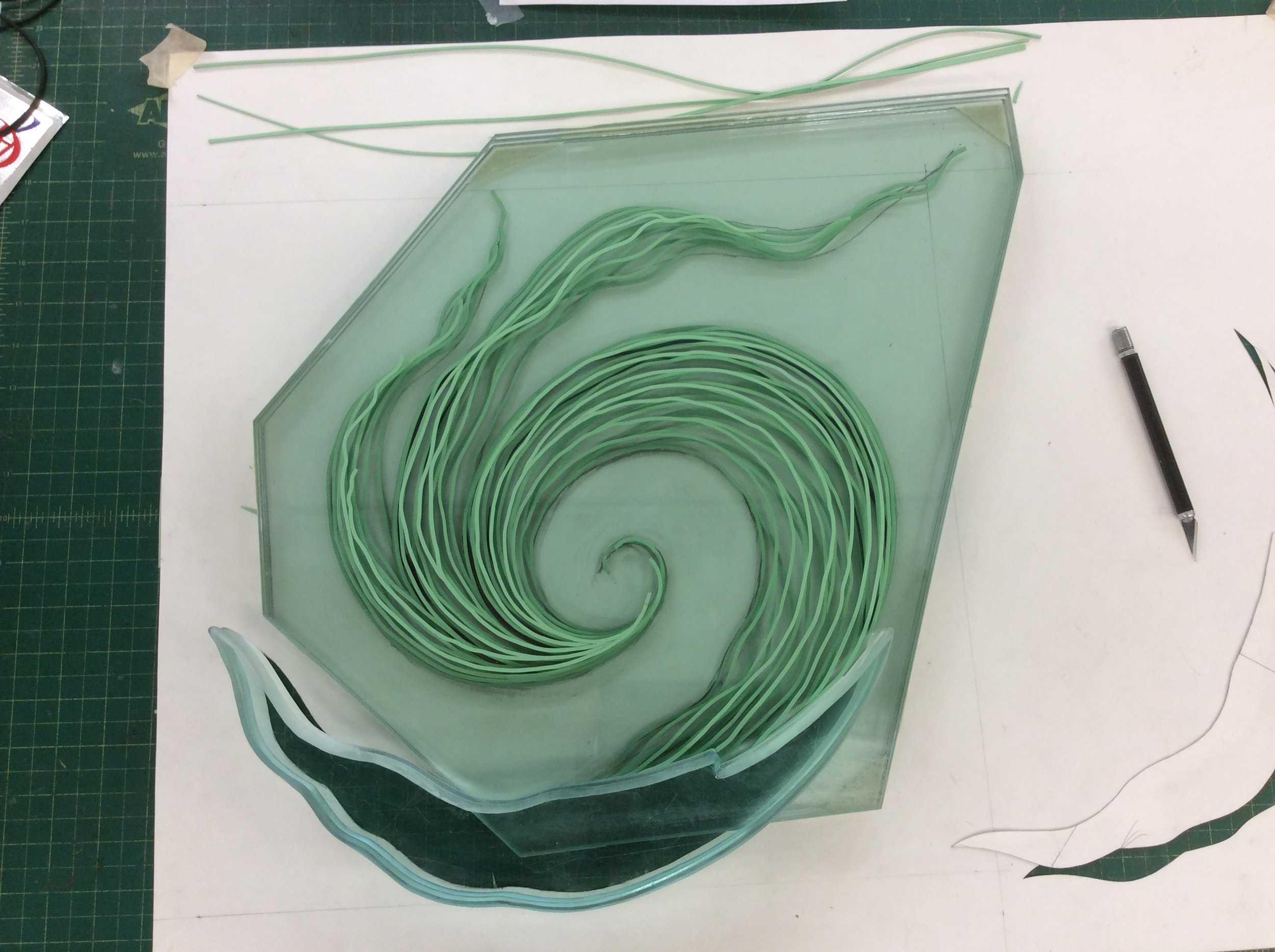

The top half is designed with rubber strips with an adhesive backing on 1/4” sheets of glass

The design is completed on 7 layers of plate glass.

The individual layers are sandblasted from each sheet of glass.

The outer layers of the bottom half are cut out of 1/2’ plate glass.

After gluing 7 layers together, the bottom surface is ground to fit the bottom half.

The top and bottom halves fit together.

The outer layers on the bottom half are glued on.

The bottom half with two additional layers.

The mounting armature for the stand is formed.

Pieces for the armature are made.

Pieces for the armature are arranged on the drawing to position the stand.

Holes are drilled into the bottom half of the sculpture.

The bottom half is carved with a diamond saw.

Pins are made to glue onto the bottom half.

A resist is applied to the bottom half prior to sandblasting.

The finished bottom half.

The bottom half with the pins glued into place.

A shipping crate is made….

…and lined with foam.

The finished sculpture nestled in the shipping crate.

Coriolis on display.